Pipeline Facts and Figures

Australia’s gas transmission pipeline system

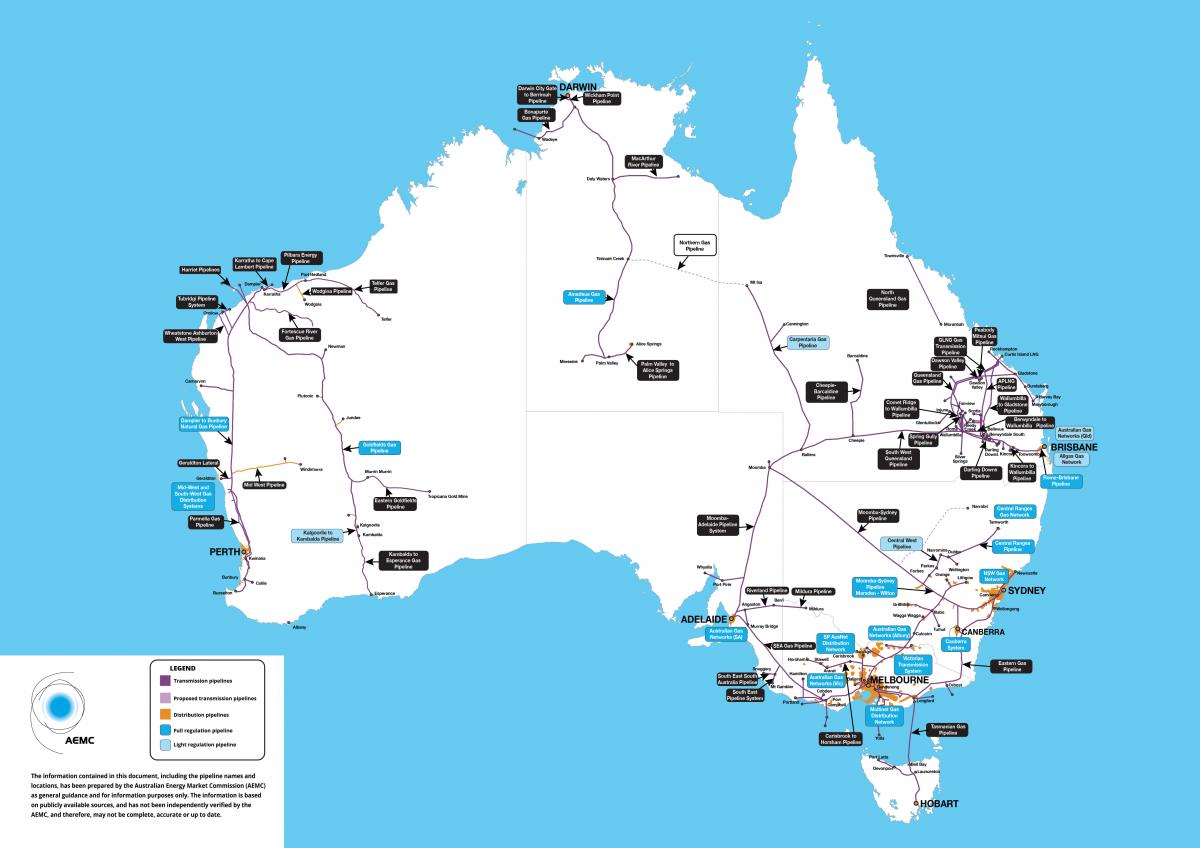

Australia has around 42,000km of natural gas transmission pipelines that efficiently transport gas under high pressure from where it is produced to the outskirts of cities both large and small. Every molecule of gas used in Australia travels at least part of the way to its destination in a transmission pipeline.

Safety first

Natural gas transmission pipelines in Australia have a good safety record that is longstanding. In addition, there has never been a major gas outage caused by a pipeline incident.

The design, construction, testing, operations and maintenance of high-pressure gas transmission pipelines made of steel are underpinned by Australian Standard 2885. The Standard was developed by a working group of industry and government members, and APGA members continue to actively participate in its design, review and development. AS 2885 is written from a safety perspective and requires extensive investigation to identify, document and control any threats to the pipeline along its entire length. It also requires regular review to ensure that any threats identified continue to require consideration and that the controls applied are effective.

The national adoption of AS 2885 by all State and Territory technical regulators and their involvement in its continued development and maintenance has enabled the pipeline industry to achieve a level of regulatory consistency not typical to every industry with state-based regulation. A key safety principle of risk assessment when designing pipelines for all environments is the ‘ALARP’ approach that all risks to the pipeline are to be kept as low as reasonably practicable (ALARP).

Each pipeline is designed to take account of the known and proposed land use and the likely risks in the range of environments through which it passes. The issues that a rural environment poses to a pipeline are very different from those encountered in urban environments.

History of pipelines

Australia’s first pipeline was commissioned in the late 1800s to transport water to the Coolgardie gold fields. This set a worldwide precedent by being more than 10 times longer than any other existing pipeline.

The Moonie to Brisbane pipeline was the first Australian pipeline built for oil transportation. It was completed in 1964 and was 306 kilometres long. At that time, it was the longest high-pressure pipeline in Australia. The 440km Roma to Brisbane pipeline came into operation in March 1969 and is Australia’s oldest natural gas pipeline.

Today, pipelines are also used to transport different forms of gas and other liquids such as oil, slurry and water.

East Coast gas grid

The transmission pipeline system is an interconnected grid covering Queensland, New South Wales, Victoria, South Australia, Tasmania and the ACT. The network enables natural gas from Bass Strait to be transported to suburban Sydney and industrial users in south-east Queensland. Gas from the Cooper and Eromanga basins also travels eastwards to Sydney and Brisbane as well as south to Adelaide. Natural gas from Bass Strait goes to Tasmania, Victoria and South Australia, and in Queensland gas is transported from the Bowen, Surat, Galilee, Cooper and Eromanga basins across the south of the State. In recent years, most transmission pipelines in the East Coast grid have been made bi-directional which means that gas produced in Queensland can be used in Tasmania and gas from Bass Strait can be sent to as far north as Gladstone where it could be exported and eventually used somewhere in Asia. This interconnectedness has enabled more flexible arrangements for trading in gas and it means gas can be sent where it is needed.

The Northern Territory has the Amadeus pipeline which takes gas from fields in the Amadeus Basin near Alice Springs to Darwin. Darwin is also an LNG hub, with multiple offshore gas fields delivering gas to the two LNG facilities there. The Northern Gas Pipeline in the NT connects its gas fields to the East Coast network, linking the Amadeus pipeline to the Carpentaria pipeline near Mt Isa in Queensland.

Western Australia

The onshore gas transmission pipeline system in Western Australia covers significant distances with the Dampier to Bunbury Pipeline at 1539km and the Goldfields Gas Pipeline at 1590km. These bring gas from offshore fields near Dampier to population centres to the south. Other transmission pipelines in WA service mines and mining towns in the Pilbara.

Efficient transport

Transmission pipelines have diameters, typically 300mm or more, and they operate under high pressure. These two factors mean that the amount of gas that can be transported is optimised. Pipelines also act as storage vessels which can assist in delivering gas in response to peaks and troughs in demand. Transmission charges amount to 3–8 per cent of household delivered gas costs, and 15–20 per cent of wholesale delivered gas costs.

More information

Pipeline construction

The first step in the construction of a gas transmission pipeline is surveying the route. Transmission pipelines can be hundreds of kilometres in length and they can pass through a wide variety of terrain with different geological and topographical features, as well as State and Territory borders. Choosing the final route depends on a number of variables, including soil types, topographical features that pose additional challenges such as river crossings and cliffs, the location of flora and fauna habitat, the presence of other utilities such as high-tension power lines, population centres, heritage sites, and land acquisition and other legislative requirements. Once the route has been selected, the process of securing all the necessary approvals begins. This is likely to include applications involving several processes in different government departments and agencies – in more than one jurisdiction if the pipeline is crossing borders – and working with local governments. While the approvals process is under way, the design engineers and community liaison officers start work.

Designing the pipeline

Transmission pipelines operate at high pressures, typically between 10,000 and 15,000 kilopascals which is up to 150 times atmospheric pressure at sea level, and this means they must be carefully designed and constructed so they are safe and reliable to operate. Australian Standard 2885 applies to high-pressure hydrocarbon pipelines and engineers in the design phase will take into account the relevant requirements of the Standard which as a significant focus on public safety. During design, engineers undertake modelling and analysis on a range of issues. The route of the pipeline will require particular designs for crossing each water course and for other obstacles, as well as for managing risk in areas where there may be traffic or similar considerations. When designing a pipeline, engineers have to consider aspects of the pipeline’s operation, such as its maximum allowable operating pressure, fatigue and fracture analysis, mitigating corrosion, modelling pressure control and over-pressure protection, the pipe wall thickness, soil mechanics and electrical influences and earthing. The designers also have to provide for compressor stations and other structures required by the pipeline and for elements related to its operation such as control systems.

Working with the community

Constructing a pipeline can bring a boost in economic activity to regional towns, but it can also mean some temporary disruption to normal life during the construction phase. Community liaison officers start working with local communities and individual land owners as soon as the pipeline’s route is decided so that everyone will understand what will happen while the pipeline is being built and how the impact on local communities can be minimised.

Making the pipe

Once the route and design are finalised, the pipe can be ordered and manufactured. Most pipe used for transmission pipelines begins as a flat sheet of steel. The sheet plate is heated and then moulded into the pipe shape, often in a two-step process: from flat to U-shape and then into a cylindrical shape. The pipe is then welded along the seam, expanded to its final size and then tested. Once it has passed the test, it is sent for coating. Before coating, rust and scale is removed, the pipe is heated and coating is applied to both the outside and inside of the pipe. Then the pipe is ready to be transported to the construction site.

Clearing the site and laying the pipe

.jpg?width=880&height=506&name=Env.%20view%20after%20reseeding%20(2).jpg)

As the pipe is being shipped to the construction site, the crews begin working at the site. Cultural heritage and environmental surveys are carried out at the site before any clearance, and then the pipeline easement is pegged out by the surveyors. Vegetation is cleared along the pipeline route and the easement is levelled. This is done carefully so that the rehabilitation of the site can be undertaken more efficiently once the pipeline has been laid. The pipeline is constructed in sections. When the pipe is delivered to the site, it is laid out end to end along the right-of-way in a practice called stringing. Then the bending crew comes along to shape the pipes to ensure they fit the terrain as required. After the bending has been completed, the pipes are welded together into a pipeline that can be up to a kilometre or so in length. The welding is a significant operation carried out by highly skilled technicians with the joins welded on both the inside and outside. The welds are thoroughly tested with ultrasonic and radiographic testers, then the outside weld is sandblasted and coated. The trench is dug, the pipeline is lowered in, and then the pipeline is covered over, with the topsoil the final layer. After rehabilitation, which usually takes little time, the land can be used again, for instance for grazing cattle.

In some situations, such as river crossings, a process called horizontal directional drilling is used to minimise the impact on the environment. In this case a hole is drilled from one side of the river to the other and then a pipe casing is pulled through the hole to the other side.

Operating the pipeline

Before the pipeline can be used for transporting gas, it must be tested to ensure it is safe to operate. The pipeline is tested by filling it with water which is then pressurised to detect any leaks. The water is pressurised to a level higher than that which will be used for transporting gas. Once all the testing is complete, gas can flow.

Testing continues once the pipeline is in operation to ensure it remains safe and reliable. Pipelines are tested for corrosion and other defects by pushing intelligent robotic devices known as smart pigs through sections of pipeline to test for thickness, roundness, corrosions, small leaks and any defects. The gas is regularly sampled and pipelines are also routinely maintained. They are clearly marked to reduce the likelihood of interference. The Before You Dig program provides information on pipeline location so that excavation activities can be carried out safely.

Further information

Research into pipelines

APGA understands the vital contribution that relevant research can make to the safe and efficient operation of the pipeline industry. The separately funded APGA Research and Standards Committee (RSC) was established more than 20 years ago and its role is to support research that is crucial to the ongoing safety, reliability and efficiency of pipelines. In addition to direct funding, APGA-RSC’s member companies also contribute valuable in-kind support that, in recent years, has brought the total value of its research program to more than $2 million a year. The committee also works closely with the pipeline committees of Standards Australia to ensure research results can be quickly applied to the industry’s highly respected national standard, Australian Standard AS 2885 – for the benefit of the industry and wider community.

Future Fuels Cooperative Research Centre

APGA, via its Research and Standards Committee, is the largest industry partner in the Future Fules CRC. The Future Fuels CRC is at the forefront of research and development to support Australia’s multibillion dollar energy sector to transition to low-carbon fuels. It works with its partners in a collaborative and connected research community embracing industry, academia and government.

More efficient use of materials for energy pipelines

The overall aim of Research Program One is to lower the cost and extend the life of energy pipelines by using materials more efficiently and avoiding material-related problems that result in economic losses. Researchers are examining welds and welding techniques, and a key goal is to produce a user-friendly industry tool for the prevention of weld-metal hydrogen-assisted cold cracking. The program is also examining methods that would increase the use of higher strength steels and assisting with the specification of line pipe steels and the determination of the mechanical properties of the steel.

Australian Standard AS 2885

The overarching Standard that applies to the pipeline industry in Australia is AS 2885. This Standard was developed by a working group from both industry and government. APGA and its members continue to actively participate in the design, review and development of the national Standard for gas and liquid petroleum high-pressure pipelines by participating as members and associates on Standards Australia development committees. AS 2885 relates to design, construction, testing, operations and maintenance of gas and petroleum pipelines that operate at pressures in excess of 1050kpa. The many other standards used by the pipeline industry are referred to in AS 2885 which is the principal document.

International research collaboration

Since the APGA Research and Standards Committee was established, its members recognised the benefits of international collaboration. As a consequence, a formal relationship was developed between the RSC and the world’s leading pipeline research organisations – the US-based Pipeline Research Council International and the European Pipeline Research Group. APGA’s links with these organisations allow RSC members confidential access to pipeline research undertaken by North American and European researchers, helping to reduce duplication of research efforts by all groups. The three research organisations also meet every two years at a Joint Technical Meeting to share results, discuss issues and determine future research priorities for the industry. The Future Fuels CRC, through the RSC, also participates in the Joint Technical Meeting.